Caustic soda in concrete

Concrete is one of the most important building materials used in various constructions. Considering the need to improve the properties of concrete and increase the lifespan of structures, the use of additives and fillers such as caustic soda in concrete mixtures has been noted. Caustic soda is a mineral filler that can enhance the mechanical properties of concrete and improve its performance. This article examines the advantages, properties, and applications of caustic soda in concrete construction.

Concrete, as a building material composed of cement, sand, water, and other additives, is utilized in many structures. By incorporating caustic soda into the concrete mixture, one can enhance its properties and increase the lifespan of the structure. This article delves into the introduction and examination of the advantages, properties, and applications of caustic soda in concrete construction.

What is concrete?

Concrete is a construction material composed of a mixture of cement, sand, aggregate, and water. This mixture is homogeneously blended and takes on a plastic shape in dry atmospheric conditions, solidifying into a firm and durable form over time. Due to its favorable physical and mechanical properties, concrete is one of the oldest and most popular construction materials used in various structures.

Cement, as the primary material in concrete, imparts mechanical properties and flexibility to concrete by combining with pozzolanic materials such as lime and coal combustion products, or by using other materials such as Portland cement, as additives. Sand and aggregates, as filler materials in concrete, fill the voids between cement particles and contribute to the strength and hardness of concrete. Water is also used for the chemical reaction of cement and as a plasticizing agent for concrete.

Concrete, due to properties such as resistance to compression, flexural strength, lightweight, fire and corrosion resistance, thermal and sound insulation, injectability, formability, and bonding strength with various materials, is used in the construction industry and civil infrastructure. Common applications of concrete include the construction of concrete structures such as buildings, bridges, tunnels, dams, and public spaces. Additionally, concrete is used in other industries such as oil and gas, power plants, and water and wastewater industries.

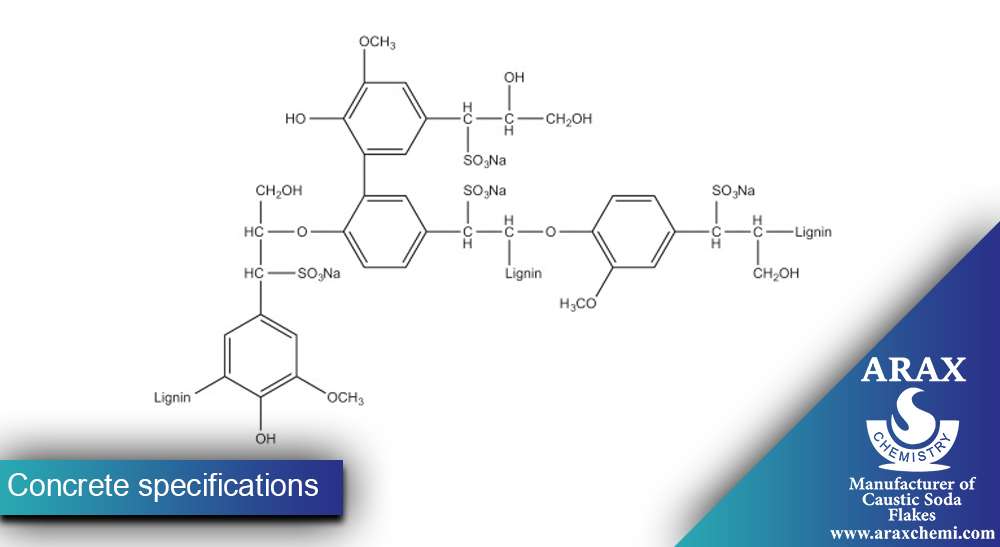

Chemical and physical properties of concrete:

Concrete, as a building material, has many chemical and physical properties that make it suitable for use in construction. Below I will mention some of the chemical and physical properties of concrete:

Chemical properties of concrete:

- Resistance to corrosion: Concrete generally has good resistance to corrosion from environmental factors such as moisture, saltwater, acids, and chemicals. This important property makes concrete valuable for structures exposed to corrosive environments.

- Heat stability: Concrete has heat resistance and can have good stability at high temperatures such as in fire. This property makes concrete popular in industries dealing with high temperatures such as fire industries and power plants.

- Insulation capability: Due to its dense and appropriate structure, concrete is suitable for insulation against moisture, heat, and sound. This property makes concrete useful in moisture control and maintaining internal conditions of buildings.

Physical properties of concrete:

- Mechanical strength: Concrete has high compressive and flexural strength. This important property makes concrete valuable for bearing heavy loads and constructing stable structures such as buildings and bridges.

- Formability: Concrete has plasticity during the mixing phase and can be shaped into various forms and dimensions. This property allows architects and engineers to create creative structures with diverse designs using concrete.

- Sound insulation: Due to its density and structure, concrete has sound insulation capability. This property makes concrete useful for reducing sound penetration and creating sound-reflective structures.

- Earthquake resistance: Concrete, due to its mechanical strength and ability to withstand shape changes, can have relative resistance against earthquakes. The use of concrete in structures, including buildings and bridges, helps reinforce and create stability against seismic forces.

Applications of caustic soda in concrete construction

Self-compacting concrete

Caustic soda is commonly used as an additive in self-compacting concretes. Self-compacting concrete is a type of concrete that is automatically filled without the need for mechanical vibration and, due to its special properties, has the ability to fill very complex and narrow spaces. Caustic soda reduces the setting time of concrete and increases its plasticity, allowing the concrete to automatically fill narrow spaces without the need for mechanical vibration.

Concrete structures with heavy loads

Caustic soda is used as an additive in concrete to increase its compressive and tensile strength. These properties make the concrete suitable for use in structures and buildings subject to heavy loads. Concrete with caustic soda can have greater resistance to external loads and prevent damage caused by these loads.

Structures susceptible to corrosion

Caustic soda contributes to resistance against corrosion in concrete. Concrete with caustic soda can have greater resistance to environmental factors such as saltwater, chemicals, and pH changes. These properties can protect concrete against corrosion and environmental damage, increasing the useful life of structures.

Industrial uses

Caustic soda is also used in concretes used in industrial environments. Concrete with caustic soda can have greater resistance to chemicals such as oils, acids, and alkaline solutions. This results in an increased useful life of concrete in industrial environments and reduces the need for frequent repairs and maintenance.

Effects of caustic soda in concrete

The use of caustic soda in concrete construction may lead to additional costs. These costs may arise due to the collection, purchase, and transportation of caustic soda, changes in the concrete formulation, and the labor and equipment costs required for adding caustic soda to the concrete.

Caustic soda is available as a commercial mineral additive in the market, and its price may vary depending on the source, quality, and demand. Additionally, since caustic soda is added as a concrete admixture, it may increase the consumption of cement and other necessary materials in the concrete mix, resulting in increased material costs. In addition to material and additive costs, the use of caustic soda may also require changes in the concrete formulation, laboratory testing, and engineering calculations to determine appropriate quantities. These processes require time, expertise, and financial resources, which may incur additional costs.

Overall, the costs of using caustic soda in concrete construction depend on various factors, including the type and quality of caustic soda, the amount used, local variables, and project conditions. While the use of caustic soda can create additional costs, its benefits such as improving concrete properties and the lifespan of structures can reduce long-term maintenance costs. Therefore, in evaluating the costs and benefits of using caustic soda, various factors should be carefully considered to make the right decision.

Use of perk profit: reducing the cost of concrete production

The use of caustic soda in concrete can lead to a reduction in future maintenance costs. Caustic soda is a mineral additive that is added to concrete and improves properties such as increased strength, reduced water permeability, and other mechanical and physical properties of concrete. By using caustic soda in concrete, the strength of the concrete can be increased, and properties such as abrasion resistance and resistance to corrosion can be improved. These factors can reduce the need for widespread repairs and maintenance over the lifespan of the structure. Concrete reinforced with caustic soda can have greater resistance to temperature changes, moisture variations, and external forces such as earthquakes.

Additionally, caustic soda can help reduce water permeability in concrete. Water and moisture are major factors in repairs and maintenance. By reducing water permeability in concrete, the entry of moisture and contaminants into the concrete structure is prevented, which can cause a decrease in quality and structural damage. By increasing resistance to water permeability, future repair and maintenance costs are reduced. Therefore, the use of caustic soda in concrete can contribute to the lifespan of the structure, reduce repair and maintenance costs, and improve concrete performance. However, the additional costs associated with purchasing and adding caustic soda should be compared with the benefits of increased lifespan and reduced maintenance costs in the future to make an appropriate decision.

pros & cons of using caustic soda in concrete

Advantages

- Improved Concrete Performance

Caustic soda can control the setting time of concrete. If concrete has a longer setting time, its strength will also be greater. This can be useful in situations where there is a need for rapid use of concrete. Typically, caustic soda reduces the setting time of concrete and increases its strength in a shorter time.

- Reduced Water Requirement

The use of caustic soda can help reduce the amount of water needed for concrete preparation. This can be achieved in two ways. Firstly, caustic soda can increase the plasticity of concrete, allowing water to be well distributed within the concrete. Secondly, caustic soda can reduce water in concrete, meaning less water is needed to achieve a specific performance in concrete.

- Improved Mechanical Properties

Caustic soda can also improve the mechanical properties of concrete. This includes increasing compressive strength, tensile strength, and flexibility of concrete. With increased concrete strength, it can be used in structures and buildings with heavier loads and prevent damage from external loads. Additionally, concrete resistance to thermal and moisture variations is also improved.

- Corrosion Resistance

The use of sodium hydroxide can increase concrete’s resistance to corrosion and environmental factors such as saline water, chemicals, and pH changes. These properties can protect concrete against corrosion and environmental damage, increasing the lifespan of the structure.

- Reduced Shrinkage

Caustic soda can reduce concrete shrinkage and, in other words, prevent cracking and damage caused by shrinkage. Concrete shrinkage usually occurs due to changes in water volume during the concrete formation process. By using caustic soda, this shrinkage is reduced, improving the density and strength of the concrete.

Disadvantages

- Risk of alkali silicate formation

Using large amounts of caustic soda may cause the formation of alkali silicate in concrete. This material can react with minerals in concrete and form alkali silicate, which can lead to destruction and reduction of concrete strength.

- Risk of burns

As a strong alkaline substance, caustic soda interacts with the skin and eyes and can cause reactive burns if they come into direct contact with them. If caustic soda is used, direct contact with skin and eyes should be avoided and necessary precautions should be observed

- Potential for environmental pollution

Excessive use of caustic soda may lead to water and soil pollution. Therefore, the consumption and disposal of caustic soda should be done in accordance with the instructions and laws of the environment in order to prevent damage to the environment and its pollution.

Conclusion

In conclusion, the use of caustic soda in concrete production can improve the properties and performance of concrete and increase the lifespan of structures. Caustic soda is an additive that can increase the compressive and flexural strength of concrete, reduce permeability, and enhance concrete’s resistance to corrosion and heat. Therefore, the use of caustic soda in concrete construction is widely recognized and yields desirable results. By adding caustic soda to concrete, benefits such as increased mechanical strength, reduced water permeability, increased resistance to bending and compression, and enhanced resistance to corrosion and heat are achieved. Additionally, the use of caustic soda can extend the lifespan of structures and require less maintenance and repair over time. However, the use of caustic soda also comes with disadvantages. These include the additional cost of using caustic soda. The price of caustic soda is higher than that of plain concrete, and the production and application costs may also be higher. Furthermore, the use of caustic soda may result in changes in the color and appearance of concrete, which some projects consider as a significant issue. Moreover, the use of caustic soda may reduce the initial strength of concrete.