Plastics hold a special place as one of the most important engineering materials in modern life. Plastics play a vital role in food packaging, automotive parts, medical equipment, and even electronic devices.

But have you ever wondered what makes these materials so efficient and flexible? A key component of the plastic manufacturing process is caustic soda (sodium hydroxide).

This powerful substance plays a fundamental role in preparing and enhancing plastic properties. In this article, we examine the role of Caustic Soda in the Plastics Industry and its importance in improving the quality and various characteristics of plastics.

History and Definition of Caustic Soda

Caustic Soda, also known as sodium hydroxide (NaOH), is one of the most important industrial chemicals. This strong alkaline substance is produced via the chlor-alkali process and is widely used in various industries, including paper production, soapmaking, and plastics.

Notable characteristics of caustic soda include its high alkalinity, solubility in water, and ability to react with both organic and inorganic materials.

Production Process of Caustic Soda

Caustic soda is produced via the chlor-alkali process, which involves the electrolysis of a salt solution (sodium chloride).

This process can be carried out using three different types of electrolytic cells: mercury cells, which are less commonly used due to environmental concerns; diaphragm cells, which offer higher efficiency and lower environmental risks; and membrane cells, which use ion-exchange membranes and are superior in terms of efficiency and environmental impact.

For more detailed information, refer to an article on the production of caustic soda using the diaphragm method.

The Manufacturing Process of Plastics and the Role of Caustic Soda

In the manufacturing of plastics, raw materials must be appropriately processed to achieve the desired properties. Caustic soda is used in several stages of this process:

Monomer Preparation

Monomers are the building blocks of polymers. In many cases, monomers are produced through complex chemical reactions that require alkaline conditions. Caustic soda, which is a strong alkaline substance, provides a suitable environment for these reactions.

Polymerization

Polymerization is the process in which monomers are converted into polymer chains. At this stage, caustic soda can act as a catalyst or pH regulator. Regulating the pH during polymerization is crucial because minor changes can significantly affect the quality and final properties of the plastic.

Improving Plastic Properties

The produced plastics may need modification and improvement of their properties. Caustic soda is also used at this stage to enhance its flexibility, heat resistance, and durability. This substance can help alter the molecular structure of plastics and impart desirable features.

Applications of Caustic Soda in the Plastics Industry

Caustic soda is used in the plastic industry for polymer production, surface treatment, plastic recycling, and resin modification.

This substance contributes to the efficiency and quality of various plastics with diverse properties.

For more information on the application of caustic soda in the plastic industry, please refer to the following article:

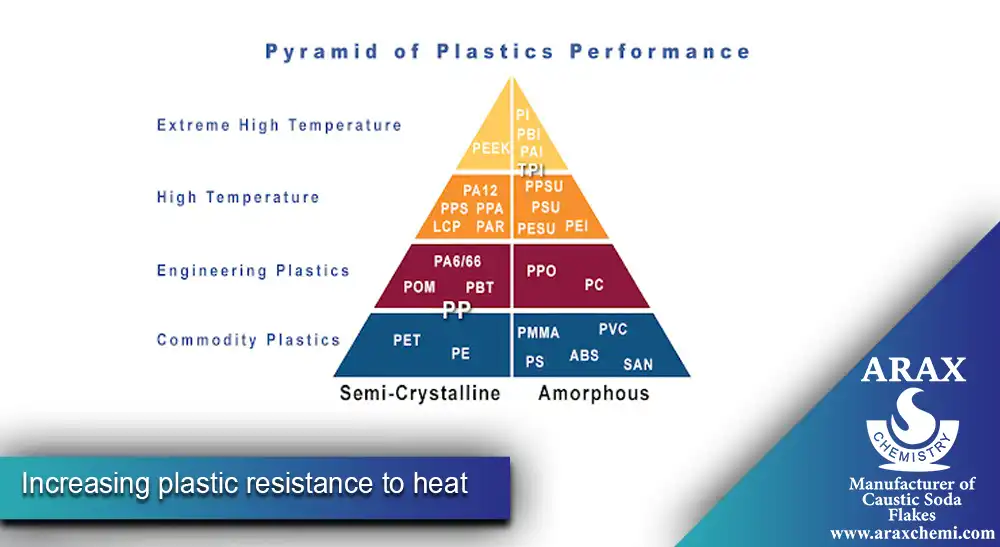

Increased Heat Resistance Plastics

processed with caustic soda often exhibits high heat resistance. Caustic soda enhances the thermal stability of polymers by affecting their chemical structure.

This increased heat resistance is critical for applications in which plastics are exposed to high temperatures, such as automotive parts, electronic devices, and cooking utensils.

In these cases, plastics reinforced with caustic soda can withstand higher temperatures without losing their mechanical and chemical properties.

Flexibility

Flexibility is one of the key features of plastics that can be improved using caustic soda. Sodium hydroxide helps optimize the polymer chains. This process involves adjusting the length and distribution of polymer chains to form flexible plastics.

Higher flexibility means that plastics can better resist shape changes and mechanical pressure without breaking or deforming. This feature is particularly important for products like plastic films, packaging, and flexible components.

Resistance

Plastics produced using caustic soda often exhibit greater chemical resistance.

Caustic soda creates stronger chemical bonds in the polymer structure, making these polymers more resistant to chemical reactions.

This feature is highly beneficial in various industries, including chemical packaging, medical equipment, and industrial parts that require resistance to corrosive chemicals.

Chemically resistant plastics can outperform harsh and corrosive environments without altering their physical and chemical properties.

Caustic Soda plays a significant role in the production of certain polymers

Here are two examples:

- Polyvinyl Chloride (PVC)

Caustic soda is used as a catalyst in the chlorination of ethylene dichloride to produce vinyl chloride, which is then polymerized to form PVC. Sodium hydroxide acts as a catalyst in this process, facilitating the conversion of vinyl chloride to PVC. - Polyethylene (PE)

In the production of polyethylene, caustic soda is used as a catalyst in the process of converting ethanol to ethylene and then to polyethylene. This helps improve the final product quality by acting as a catalyst.

Overall, caustic soda is used as a catalyst and an auxiliary agent for the production of specific polymers, enhancing the quality of the final product, and facilitating reactions.

Benefits and Cons of Caustic Soda in the Plastics Industry

benefits

- High Efficiency: Caustic soda is highly efficient for plastic production because of its strong alkalinity.

- Cost effective: Caustic soda is more cost effective than other chemicals.

- Improvement of Properties: This substance can enhance the physical and chemical properties of plastics.

Cons

- Safety Hazards: Caustic soda can cause skin and eye damage and requires strict safety precautions.

- Environmental Concerns: Improper disposal of caustic soda can harm the environment.

Impact and Waste Management of Caustic Soda

The widespread use of sodium hydroxide in various industries, including the plastic industry, has resulted in specific environmental issues.

Caustic soda is a strong alkaline substance, and improper disposal can damage the environment. Therefore, proper management of waste containing caustic soda is crucial.

Waste Management Methods

Neutralization: One common method for managing caustic soda waste is its neutralization with acids, which produce less harmful salts and water.

Recycling: Caustic soda is recyclable and can be reused in industrial processes.

Recycling caustic soda not only reduces costs but also prevents environmental pollution.

Water Treatment: When caustic soda is added to industrial wastewater, it is essential to treat this wastewater before discharge to prevent water source contamination.

Research and Innovations in Caustic Soda Use

Many scientific studies are ongoing regarding the use of “caustic soda” in the plastic industry. These studies identified new and improved methods for using caustic soda in plastic production.

Improving Production Processes

One key research area is improving plastic production processes using caustic soda with the aim of increasing efficiency and reducing production costs. For instance, researchers are exploring the use of new catalysts and optimizing polymerization methods.

Caustic soda and biodegradable polymersBiodegradable plastics are proposed as alternatives to traditional plastics, which cause significant pollution. Caustic soda also plays a crucial role in the production of these types of plastics.

Research in this field has identified compounds and processes that help produce high-quality, efficient biodegradable polymers.

Caustic Soda in Nanotechnology

Nanotechnology, one of the latest scientific advancements, has broad applications in various industries, including plastics.

Caustic soda is used in the production of nanomaterials and other materials. These studies aim to find new methods for producing nanoplastics with improved properties.

Case Studies on the Use of Caustic Soda

The use of caustic soda in the plastics industry has been examined as a pH regulator and catalyst in the production of PVC. One study in this field showed that using caustic soda significantly improves the PVC production process and enhances the physical properties of this polymer.

In the field of biodegradable polymers, the use of caustic soda as a catalyst has also been examined. A previous study demonstrated that using caustic soda in the production of these types of polymers can help produce high-quality, durable products. Additionally, studies have been conducted in nanotechnology, focusing on the use of caustic soda in nanoplastic production. These studies have shown that caustic soda can improve the properties of nanoplastics, including their heat and chemical resistance.

Conclusion

Caustic Soda is a key component in the production and improvement of plastics.These powerful chemical substances significantly enhance the various properties of plastics, rendering them suitable for diverse applications.

With increasing heat resistance, improved flexibility and chemical resistance, caustic soda has played a vital role in the plastic industry. Despite some challenges and the need to follow safety protocols, the numerous benefits of using caustic soda cannot be overlooked.

Frequently Asked Questions

- Why is caustic soda used in plastic production?

Caustic soda is used due to its strong alkaline properties to improve features such as heat resistance, flexibility, and chemical resistance in plastics. - Is it safe to use caustic soda in Plastics?

caustic soda in the plastic production process can be safe if safety principles and proper management are followed. This substance should be used carefully and under controlled conditions to minimize potential risks. - What are the alternatives to caustic soda in plastic production?

can also be used in the plastic production process, but caustic soda remains one of the primary choices in this industry because of its low cost and high efficiency.