Caustic soda, or sodium hydroxide, is a strong chemical compound that is used in various industries as a powerful alkali. Due to the unique properties of caustic soda, it finds applications in several industries. Some of the caustic soda uses include glass manufacturing, mining, water treatment, desalination plants, and food processing. What is important in the article about the applications of caustic soda in industry is that you understand the necessity of using caustic soda in industry. This knowledge not only increases your awareness of industrial products but also enables you to make successful choices in selecting the necessary materials for your industry.

caustic soda uses at a glance

Caustic soda, also known as sodium hydroxide, caustic lye, or (NaOH), is a colorless and odorless chemical compound that is available in solid, flaked form in the market. Due to its solubility and alkalinity, this substance is widely used in many household and industrial applications. Its unique properties, such as cleaning, disinfecting, and pH regulation, make it one of the primary chemicals used in the production of soap, detergents, rinsing agents, paper, plastics, pesticides, as well as in the oil, gas, and petrochemical industries.

Caustic soda reacts strongly with acids and alkaline substances and can cause burns, eye and skin irritation, shortness of breath, and even burns on the hands and feet. Therefore, when using caustic soda, it’s essential to protect skin and eyes and keep it out of reach of children and pets. Due to its high alkalinity, caustic soda can also damage sensitive surfaces such as plastics, delicate metals, and leather.

| Medicine and Pharmacy | Aluminum Production | Leather Industry | Refinery |

| Soap Production | Textiles and Fabric Production | Concrete Production | Cosmetics and Personal Care Industry |

| Water Treatment | Organic Chemicals | Dyeing Industries | Automotive Industry |

| Glass Industry | Food Industry | Plastic Recycling | Battery Acid Neutralization |

| Detergents | Catalytic Activity | Car Wash | Ceramics Industry |

| Plastic Production | Energy Production | Shampoo Production | Fertilizer Production |

| Adhesive Manufacturing | Cement Industry | Dairy Industry | Vegetable Oil Production |

| Paint Production | Dissolution of Metals and Amphoteric Compounds | Carpet Cleaning | Olive Brining |

| Pulp and Paper Production | Vegetable Oil Refining | Oil Refining | Degreasing in Industry |

| Petroleum Products Production | Mineral Production | Furniture Industry | Drilling |

- Caustic Soda flakes Uses in industry

Comparison of the Physical Appearance of Caustic Soda with Its Chemical Properties

| Chemical characteristics | Physical characteristics |

| Chemical formula: NaOH | Appearance: crystalline solid |

| Molecular weight: 40.00 g/mol | White color |

| Chemical composition: one sodium atom (Na) and one hydroxyl group (OH) | Odor: Odorless |

| Melting point: 318 degrees Celsius | Taste: Bitter alkaline taste |

| Boiling point: 1,388 degrees Celsius | Physical state: solid at room temperature and liquid in water solution |

| Density: 2.13 grams/cubic centimeter | Density: about 2.13 grams per cubic centimeter |

| Solubility in water: soluble in water and in this case it forms sodium (Na+) and hydroxide (OH-) ions. | Solubility: Caustic soda is soluble in water and in this case it forms sodium (Na+) and hydroxide (OH-) ions. |

| pH: around pH 14, which indicates its strong alkalinity. | |

| Chemical properties: Caustic soda is a strong alkali and has the ability to precipitate, neutralize acids and break down fats. |

Production of caustic soda

Solid sodium hydroxide is actually produced from liquid sodium hydroxide with a purity of 30% to 50%. The production process of caustic soda flakes begins by transporting liquid sodium hydroxide with 50% purity to caustic soda production factories using specialized tankers. Then, in the concentration lines, the water in the liquid sodium hydroxide is evaporated, and through several stages, under careful monitoring, the liquid sodium hydroxide is transformed into solid caustic soda flakes with a purity of 98-99%.

Different types of caustic soda production

Different types of caustic soda production |

|

| It is used to produce caustic soda, but it has limitations. Mercury is a dangerous substance for the environment and there is no safe technology to work with it. In this method, mercury plays the role of the cathode, and with the production of sodium, sodium hydroxide is produced. But due to the dangerousness of mercury and safety restrictions, the use of this method is now less. |

Mercury cell method |

| It is used with asbestos separator to produce sodium hydroxide and chlorine. This method includes the use of cell drinks that contain sodium hydroxide and salt. To prepare sodium hydroxide solution with a concentration of 50%, lime is evaporated to increase the concentration and remove excess salt. Diaphragm cells can be more economical than mercury cells in cases where the price of steam is low and also cost less to build. You can refer to the diaphragm method article for more information |

Diaphragm method |

| In the electrolysis process, a salt solution of sodium chloride (NaCl) is used as a raw material. In this process, an electrolysis cell is used, which includes two electrodes (anode and cathode) and a salt solution. In the anode of the electrolysis cell, sodium chloride (NaCl) is oxidized to chlorine (Cl2). This chlorine is collected in a part of the cell. In the cathode of the electrolysis cell, sodium ions (Na+) are reduced to sodium hydroxide (NaOH) and hydrogen (H2). Sodium hydroxide (caustic soda) is formed in the solution. By combining the collected chlorine and caustic soda, it is possible to produce chlorine-alkali (chlorine and caustic soda), which is used in various industries. |

Electrolysis method |

40 Comprehensive Uses Of Caustic Soda Worldwide

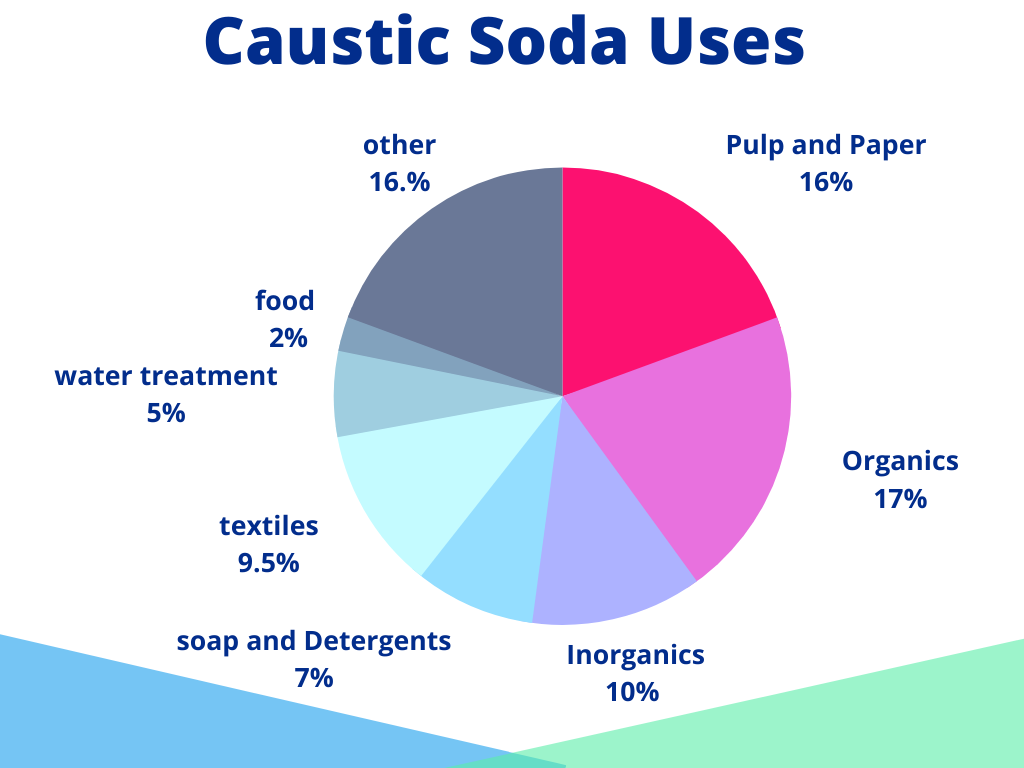

The applications of caustic soda are very extensive, with its most significant uses in the chemical and food industries. In the chemical industry, it serves as a raw material for producing soap, glass, medicines, paints, adhesives, plastics, cleaning agents, and more. Below, we introduce each industry where caustic soda is used and explain its applications.

1) Application of Caustic Soda in Glassmaking

Caustic soda (NaOH) is a key ingredient in the glassmaking industry, used both in the production and cleaning of glass. It reduces the melting temperature of glass and helps regulate its properties. Additionally, adding caustic soda enhances the flexibility of the glass and facilitates its shaping. It is also used in smoke purification during glass production and improves the clarity of the glass.

2) Application of Caustic Soda in Water Treatment

In water treatment, caustic soda raises the pH of water, removes heavy metals like lead, zinc, and cadmium, and helps reduce harmful pollutants. Municipal water treatment plants and wastewater facilities use caustic soda to control water acidity and aid in removing heavy metals. Sodium hydroxide is also used to produce sodium hypochlorite, a water disinfectant.

3) Application of Caustic Soda in Soap Production

Caustic soda is used in soapmaking as a softener, buffer, and stabilizer. It softens the soap, enhances its cleaning properties, and improves its ability to absorb unpleasant odors. It also helps create air bubbles in the soap, improving its fragrance and overall quality.

4) Application of Caustic Soda in the Medical and Pharmaceutical Industry

Caustic soda is an essential material in the medical and pharmaceutical industries. It is used for disinfecting medical instruments, in dentistry, and in skin treatments. In pharmaceuticals, it is employed to regulate pH in formulations, clean and sanitize pharmaceutical equipment, and is used in bile preparation and drug production processes.

5) Application of Caustic Soda in the Paint Industry

Caustic soda is used in paint production as an etching agent, pH regulator, dyeing aid, antioxidant, plating material, and color stabilizer. It is mainly used to stabilize colors during paint production.

6) Application of Caustic Soda in Adhesive Production

In the adhesive industry, caustic soda is used for:

- Regulating the pH of adhesive mixtures

- Enhancing adhesive strength

- Acting as a catalyst during drying

- Protecting adhesives from oxidation and color changes

- Controlling the viscosity of adhesives

7) Application of Caustic Soda in Plastic Manufacturing

Caustic soda is used in:

- Plastic recycling

- Surface cleaning and descaling of plastics

- Disinfection and treatment of plastic surfaces

- As a raw material in producing plastic chemicals

- Controlling chemical processes in molding and shaping plastics

8) Application of Caustic Soda in Detergent Industry

Caustic soda is widely used in the detergent industry as a strong cleaning agent. Its main applications include laundry cleaning, surface cleaning, appliance cleaning, glass and mirror cleaning, and pipe and irrigation system cleaning. However, safety precautions should be followed when using caustic soda.

9) Application of Caustic Soda in Textile Industry

In the textile industry, caustic soda is used for processing cotton and dyeing synthetic fibers such as nylon and polyester. It is also employed to stabilize and improve the color of fabrics and remove grease from fibers.

10) Application of Caustic Soda in Aluminum Production

Caustic soda is used to dissolve bauxite ore, the primary material in aluminum production. It removes impurities quickly, improving the quality of the final output by dissolving aluminum oxide and silicon in the bauxite. Caustic soda is used in chemical industry, glass making. In the chemical industry, it is used as a raw material in the production of soap, glass, medicines, paints, adhesives, plastics and detergents. Also, in soda glass industry. Caustic soda is also used in water purification.

11) Application of Caustic Soda in Petroleum Product Production

Caustic soda is primarily used in the exploration, production, and processing of oil and natural gas. Its other applications include oil refining, oil treatment, improving fuel quality, cleaning chemical equipment, and regulating pH. The use of caustic soda in petroleum products not only enhances the quality of the produced products but also increases the efficiency of refining materials.

12) Application of Sodium Hydroxide in Pulp and Paper Production

One of the largest applications of caustic soda worldwide is in the paper industry. Its uses include pulping and bleaching processes, deinking waste paper, and water treatment. In these processes, caustic soda, being a strong alkaline substance, is used to break down lignin, facilitate bleaching, and regulate pH. For more information, you can refer to the article on the application of sodium hydroxide in paper recycling.

13) Application of Caustic Soda in Energy Production

In the energy sector, caustic soda is used in fuel cell production. Fuel cells, like batteries, generate clean and efficient electricity for a wide range of applications, including transportation, material transfer, and backup power for fixed, portable, and emergency systems. Epoxy resins produced with sodium hydroxide are used in wind turbines.

14) Applications of Caustic Soda in Catalytic Activities

Another application of caustic soda is as a catalyst in various chemical processes. For example, when a base is needed as a catalyst in any reaction, sodium hydroxide is commonly used in laboratories for such activities.

15) Applications of Caustic Soda in the Food Industry

Caustic soda is used for the chemical peeling of green fruits and vegetables. It is also employed in processing chocolate, soft drinks, and thickening ice cream. Olives are softened by soaking them in caustic soda solution. Pretzels and German pastries can be crisped using caustic soda. Additionally, lime water is used in Chinese mooncakes and noodles. It is used for the jelly-like appearance in century eggs. Caustic soda is also utilized in Norwegian foods, such as lutefisk, to achieve a unique flavor profile. It is used for peeling vegetables (potatoes, tomatoes) as well.

16) Applications of Caustic Soda in Organic Chemicals

Caustic soda is used in industrial organic syntheses for pH control, gas-free cleaning, dechlorination, and neutralizing acids. It also acts as a catalyst during the industrial synthesis of organic compounds. In the production of emulsified polymer isocyanates (EPI), caustic soda is used for dechlorinating epoxy resins. Sodium hydroxide maintains pH in solutions for the formation of chelating agents. It is involved in the synthesis of cellulose ethers through reactions with cellulose and monochloroacetic acid. It is also used in producing cellulose derivatives such as ethyl cellulose, methyl cellulose, and carboxymethyl hydroxyethyl cellulose.

17) Application of Sodium Hydroxide in Mineral Production

Caustic soda is used to produce sodium hypochlorite (bleaching chemicals) and to synthesize sodium cyanide and zeolite. It is also utilized in producing filler compounds like sodium silicate and sodium phosphate. Generally, due to its reactivity and ability to enhance decomposition power, sodium hydroxide is employed for various mineral compound preparations.

18) Applications of Caustic Soda in Vegetable Oil Refining

The first step in neutralizing trans fatty acids in vegetable oil synthesis involves refining edible oils with a 10% caustic soda solution, which is then processed for further bleaching and deodorization. Caustic soda in vegetable oil helps remove phospholipids and other impurities, enhancing the final oil quality. Ultimately, this substance combines with pigments and odor compounds, effectively eliminating their unpleasant smells. For more amazing applications of caustic soda in producing various oils, you can refer to the article on the applications of caustic soda in the vegetable oil industry.

19) Applications of Caustic Soda in Dissolving Metals and Amphoteric Compounds

Caustic soda provides an alkaline environment for dissolving metals and amphoteric compounds such as aluminum, zinc, and lead. For example, when caustic soda reacts with aluminum and water, it produces hydrogen gas and sodium aluminate as final products. Sodium aluminate is highly useful for producing further compounds on an industrial scale. Similarly, the reaction of caustic soda with zinc and lead produces sodium zincate and sodium plumbate, respectively.

20) Applications of Caustic Soda in the Cement Industry

Caustic soda is used in cement production for various purposes. It helps reduce the separation of silica and cement and decreases the amount of water required for the cement mixture, thereby increasing the strength of cement products. These are just some of the applications of caustic soda in the construction and cement production industries. For more information, you can refer to the article on the application of caustic soda in the cement industry.

21) Applications of Sodium Hydroxide in Plastic Recycling

Sodium hydroxide is used as a depolymerizing agent in the plastic recycling process. By mixing plastic with sodium hydroxide and applying heat, the connections between the polymer chains of the plastic are broken. This process, known as hydrolysis, causes the plastic to decompose into smaller molecules. The application of sodium hydroxide allows the polymers to break down into smaller molecules that can be reintroduced into the plastic production process. These smaller molecules serve as raw materials in the production of new plastics.

22) Applications of Sodium Hydroxide in Dyeing Industries

Sodium hydroxide (NaOH) is a widely used and powerful chemical that serves as a strong base and alkali in various industries. This chemical compound can alter the pH of solutions and provide various properties in industrial processes. One of the significant applications of sodium hydroxide is in dyeing industries. The use of sodium hydroxide in dyeing can have substantial effects on both the process and the final outcome of dyeing. If you are interested in exploring the remarkable applications of sodium hydroxide in dyeing industries, you can read the relevant article on the Arax Chemical website.

23) Applications of Sodium Hydroxide in Concrete

Concrete is an integral part of the construction industry. Improving the quality of produced concrete positively impacts construction work, and with better quality, the lifespan of building structures increases. Sodium hydroxide is used as an additive and filler in concrete production, enhancing its chemical and physical properties. Although adding sodium hydroxide increases production costs, the outcome ultimately reflects in the durability and longevity of the structures. For further information, you can refer to the article on the applications of sodium hydroxide in concrete production.

24) Applications of Sodium Hydroxide in the Leather Industry

Sodium hydroxide is utilized in the degreasing and depilating processes of animal hides. Specifically, it is applied in stages where hides need to remove excess fats, such as in sheep hides, which contain a lot of fat. Due to its high corrosiveness and affordable price, sodium hydroxide is highly regarded in the leather industry. For more details, refer to the article on the applications of sodium hydroxide in the leather industry.

25) Applications of Sodium Hydroxide in Carpet Cleaning

Up to this point, we have examined the uses of sodium hydroxide. Sodium hydroxide (caustic soda) is a powerful cleaner in carpet washing. Carpet cleaning is a fundamental process in maintaining and preserving carpets and is of great importance. However, one of the challenges in this industry regarding carpet cleaning is the proper use of sodium hydroxide. Sodium hydroxide is one of the strong alkaline chemicals used for deep cleaning carpets. Its grease-dissolving power eliminates stains, dirt, and grease from carpets, contributing to their cleanliness and brightness. To learn about other applications of sodium hydroxide in carpet cleaning, refer to the article produced by Arax Chemical.

26) Applications of Sodium Hydroxide in the Dairy Industry

Sodium hydroxide (NaOH) is a fundamental chemical widely used in many industries, including the dairy industry. This chemical compound, known for its strong alkaline properties, serves as an efficient chemical in the dairy industry. The applications of sodium hydroxide in dairy include pH regulation, accelerating fermentation processes, cleaning and disinfecting equipment, altering color and flavor, and increasing the shelf life of dairy products. For a more in-depth understanding of the applications of sodium hydroxide in the dairy industry, consult the comprehensive article by our experts.

27) Applications of Sodium Hydroxide in Shampoo Production

Shampoos are classified as synthetic anionic cleansers. A suitable shampoo cleans the skin and hair without leaving adverse effects and contributes to hair shine. It also allows for easy rinsing and combing of hair. Additionally, a good shampoo removes excess oil from hair and prevents static electricity from building up (so hair does not stand on end when brushed), and it should not irritate the eyes or skin. Sodium hydroxide, as a strong alkaline chemical, has numerous applications in detergents. It is used in shampoos, but the quantity must adhere to specific standards.

28) Applications of Sodium Hydroxide in Car Washes

Sodium hydroxide serves as a strong chemical in car washes as a potent cleaner for removing tough dirt and grease from vehicle surfaces. Due to its high alkalinity, it effectively dissolves oils, greases, and hard deposits, leading to greater vehicle shine. The application of sodium hydroxide in car washes is typically in the form of a solution in water. It is essential to dilute it sufficiently during use in car washes to ensure human safety. If you are interested in learning about the uses of sodium hydroxide in car washes, you can refer to the article on the applications of sodium hydroxide in car washing.

29) Applications of Sodium Hydroxide in the Cosmetics and Hygiene Industry

Sodium hydroxide is a foundational substance in the production of any cosmetic and hygiene product. When combined with oils and fats, sodium hydroxide initiates a saponification reaction. Moreover, it plays a role in adjusting the pH of certain cosmetic products, potentially enhancing their effectiveness and shelf life. Due to its high alkalinity, the amount used in products should be sufficient to avoid skin damage. Be sure to read about the applications of sodium hydroxide in shampoo production.

30) Applications of Sodium Hydroxide in Refineries

Sodium hydroxide is used in refineries as a fundamental substance in the purification of crude oil products and petroleum products. It is employed in various processes, such as removing sulfuric acid compounds and sulfur compounds from crude oil. By neutralizing these compounds, sodium hydroxide helps improve the quality of final products such as gasoline, diesel, and kerosene and prevents corrosion of refinery equipment.

31) Applications of Sodium Hydroxide in the Furniture Industry

Sodium hydroxide has several applications in the furniture industry. Firstly, it is used as a cleaner and degreaser in the pre-manufacturing and preparation processes for wood. Caustic soda helps wood or the primary structure of furniture eliminate any impurities, grease, and resin. This improvement enhances the quality of painting and the final construction result. Another application of caustic soda in the furniture industry is for restoring and renewing old furniture. It removes old lacquer and paint layers, making the wood suitable for the next furniture construction. If you are interested in learning more about the uses of sodium hydroxide in the furniture industry, you can refer to the article on the applications of caustic soda in the furniture sector.

32) Applications of Sodium Hydroxide in Oil Refining

One of the important applications of sodium hydroxide (caustic soda) is in oil refining. In the oil refining process, sodium hydroxide is used to remove impurities and acid contaminants present in crude oil. This substance reacts with acid and sulfur compounds in crude oil, converting them into separable materials. For example, some applications of caustic soda in the oil industry include its use in the sweetening of crude oil and improving the quality of final products such as gasoline and diesel. Additionally, sodium hydroxide is effective in removing phenolic compounds and organic acids, which enhances catalyst performance and increases the efficiency of refineries.

33) Applications of Sodium Hydroxide in Chemical Fertilizer Production

Sodium hydroxide is used as a strong alkaline agent in the production and formulation processes of chemical fertilizers. One of the important applications of caustic soda in chemical fertilizer production is pH regulation of solutions and chemical reactions used in optimizing nitrogenous and phosphatic fertilizers. Sodium hydroxide serves as a raw material for removing impurities in the raw materials of any industry, ultimately leading to higher purity and improved final quality. In the production of some potassium fertilizers, sodium hydroxide is used to separate and purify potassium carbonate from mineral ores, which ultimately enhances the effectiveness of chemical fertilizers in agriculture. For more information, refer to the article on caustic soda in chemical fertilizers.

34) Applications of Sodium Hydroxide in the Ceramics Industry

Sodium hydroxide is used as an alkaline agent in the ceramics industry, aiding in the refinement of raw materials, enhancing the plastic properties of ceramic paste, and adjusting the pH of glazes. This substance also accelerates the drying process and increases the quality and durability of the final products. The key point in this section is the preparation and refinement of the raw materials for ceramic paste with sodium hydroxide, as their combination significantly influences the final outcome.

35) Applications of Sodium Hydroxide in Battery Acid Neutralization

Battery acid is considered a hazardous material for the environment, so it must be neutralized with a substance to eliminate its detrimental ecological effects. The best and most economical alkaline substance for neutralizing battery acid is sodium hydroxide. Sodium hydroxide should be mixed with an appropriate amount of distilled water (this should be done carefully and slowly), and then the sodium hydroxide solution is added to the battery acid. In this neutralization process, controlling the pH is crucial and should be managed with the correct amount of sodium hydroxide. For more detailed information, refer to the article on the application of sodium hydroxide in battery acid neutralization.

36) Applications of Sodium Hydroxide in the Automotive Industry

The applications of sodium hydroxide in the automotive industry are diverse. Its first application is in cleaning, degreasing, and removing oil, grease, and other contaminants from metal surfaces. This process is essential before painting and coating automotive parts. Another application in the production of aluminum parts involves using caustic soda to remove oxides and prepare aluminum surfaces for subsequent processes such as anodizing or painting. Additionally, other applications of sodium hydroxide in the automotive industry include producing certain chemicals, pH regulation, battery production, and water purification in factories.

37) Applications of Sodium Hydroxide in Drilling

Sodium hydroxide (NaOH) also has significant applications in the drilling industry. Some of these applications include:

- Sodium hydroxide is used as an alkaline agent for regulating the pH of drilling fluids. This helps control the chemical and physical properties of drilling fluids and prevents corrosion of drilling equipment.

- In drilling fluids, sodium hydroxide can assist in removing organic materials and deposits. This improvement enhances the performance of drilling fluids and increases drilling efficiency.

- In some cases, sodium hydroxide can help increase the viscosity of drilling fluids, improving the transportability of solid materials in the drilling fluids.

- The use of sodium hydroxide in drilling fluids can help reduce corrosion of drilling equipment and pipes, which increases the useful life of the equipment.

- Sodium hydroxide can serve as a raw material for producing other chemicals needed in the drilling process.

38) Applications of Sodium Hydroxide as a Degreaser in Industries

Sodium hydroxide serves as a strong degreaser in various industries, and due to its alkaline nature, it can react with fats and oils, converting them into soap. This alkaline property allows for the easy removal of fats from various surfaces. In the food, pharmaceutical, and chemical industries, sodium hydroxide is used to clean equipment and machinery. This substance can effectively remove tough fats and contaminants from metal surfaces and others. Furthermore, in some chemical processes, sodium hydroxide is utilized for breaking down fats and oils, foaming surfaces, dewatering, and eliminating fats and waste from fibers before dyeing.

39) Applications of Sodium Hydroxide in Sweetening Olives

One method for rapidly sweetening olives involves using sodium hydroxide. In the industry, factories clean olives and then place them in a sodium hydroxide solution. After two days, the olives are removed from the solution and washed. Finally, the olives are placed in a brine solution, and after ten days, the sweetened olives are ready for use. By employing sodium hydroxide and the method described, you can convert raw olives into a sweeter flavor. For more information on the application of sodium hydroxide in sweetening olives, refer to the respective article.

40) Applications of Sodium Hydroxide in Vegetable Oil Production

Sodium hydroxide is employed in the refining process of vegetable oils and impacts various stages of oil production. Some applications of sodium hydroxide in the vegetable oil industry include:

- Sodium hydroxide acts as an alkaline agent in the refining process of vegetable oils, helping to remove free fatty acids from the oil. When caustic soda reacts with fatty acids, sodium salts (soaps) are produced, which can then be separated.

- In the process of transesterification, sodium hydroxide is used as a catalyst to convert triglycerides into glycerol and free fatty acids. This process enhances oil quality and can also be applied in biodiesel production.

- Due to the high alkalinity of sodium hydroxide, it is utilized to remove undesirable colors and odors from vegetable oils, ultimately improving the final product’s quality.

- Using sodium hydroxide can reduce the acidity of vegetable oils, which increases the stability and shelf life of the oils.

- Caustic soda also aids in removing impurities and waste materials from vegetable oils.

- last word

The applications of sodium hydroxide (caustic soda) are highly diverse across various industries. This powerful compound serves as a strong cleaning agent in the detergent industry. It also has significant applications in the mining industry. Caustic soda is used as an auxiliary material in mining, adhesive production, water treatment, and more. Notable applications include mineral processing, accelerating dissolution processes, pH regulation, and controlling water activity.

The importance of sodium hydroxide in industries indicates that this substance has substantial positive impacts. With proper use and adherence to safety guidelines, caustic soda can be an effective tool in the mining sector, contributing to improved performance and reduced pollution in these industries. Therefore, caustic soda, as a chemical with widespread applications and high significance in various industries, is a powerful resource available for enhancing processes and protecting the environment.