Polypropylene vs Polyethylene are among the most widely used thermoplastics in various industries. Due to their unique physical and chemical properties, these two polymers are extensively used in packaging, piping, automotive, and textile industries. This article will explore the Polypropylene vs Polyethylene materials in terms of properties, applications, advantages, and disadvantages.

What is a Thermoplastic?

Thermoplastics are a category of polymers that become soft and moldable at high temperatures and solidify upon cooling. This characteristic allows thermoplastics to be recycled and reused. Among thermoplastics, polypropylene and polyethylene hold a special place.

Definition of Polypropylene vs Polyethylene

Polypropylene (PP)

Polypropylene is a thermoplastic polymer known for its unique physical and chemical properties, which make it widely applicable in various industries. This polymer is produced through the polymerization of the monomer propylene and has a semi-crystalline structure, giving it characteristics such as high heat and impact resistance.

Polyethylene (PE)

Polyethylene is also a thermoplastic polymer produced through the polymerization of the monomer ethylene. This polymer has a simple structure and high molecular weight, providing it with unique physical and chemical properties such as high resistance to moisture and chemicals. Due to its flexibility and impact resistance, polyethylene is used in many applications.

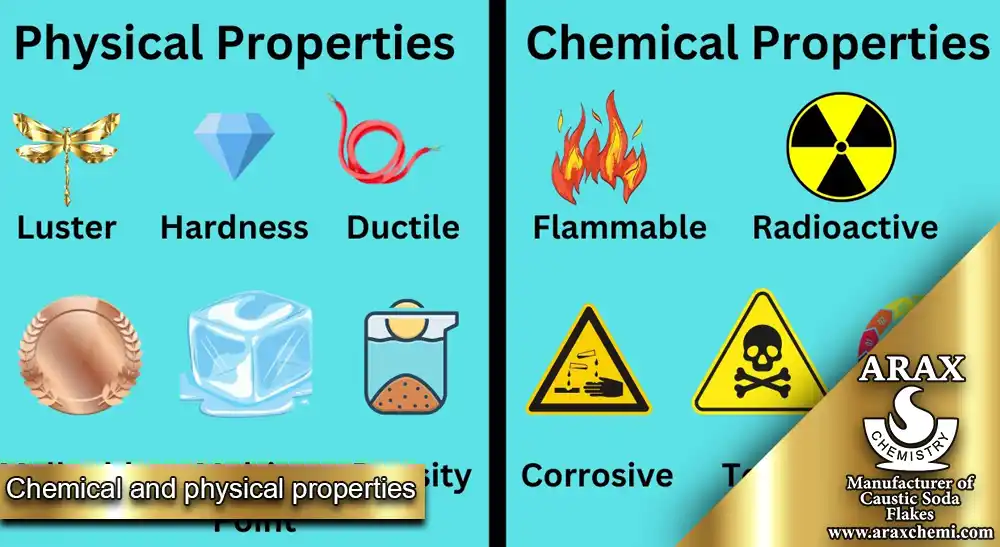

Chemical and Physical Properties

Properties of Polypropylene

Polypropylene possesses unique physical and chemical properties that distinguish it from other thermoplastics. Key properties include:

Heat Resistance: Polypropylene can withstand higher temperatures than polyethylene. Its melting point is around 160 degrees Celsius, making it suitable for applications requiring heat resistance.

Hardness and Tensile Strength: Polypropylene has high hardness and tensile strength, making it suitable for mechanical applications.

Chemical Resistance: This polymer is resistant to many chemicals, including acids and bases.

Lightweight: Polypropylene is one of the lightest plastics, offering advantages in various industries.

Properties of Polyethylene

Polyethylene also has diverse physical and chemical properties suitable for various applications. Key properties include:

Flexibility: Polyethylene has high flexibility, making it suitable for applications requiring bending and shaping.

Impact Resistance: This polymer has good impact resistance, making it suitable for impact-resistant applications.

Moisture Resistance: Due to its simple structure and high molecular weight, polyethylene has good resistance to moisture, suitable for water-resistant applications.

Chemical Resistance: This polymer, like polypropylene, is resistant to many chemicals.

Applications of Polypropylene vs Polyethylene

Applications of Polypropylene

Due to its unique physical and chemical properties, polypropylene is used in various industries. Key applications include:

Packaging: Due to its impact and heat resistance, polypropylene is used in food and pharmaceutical packaging. It is also used to produce packaging films, plastic containers, and bottles.

Textiles: Polypropylene is used in producing industrial and non-industrial fibers and fabrics such as carrying bags, carpets, and sportswear.

Automotive: Due to its lightweight and high resistance, this polymer is used to produce automotive parts such as bumpers, dashboards, and interior covers.

Household Goods: Polypropylene is used in producing household goods such as kitchen utensils, toys, and electronic components.

Applications of Polyethylene

Polyethylene is also used in various industries due to its diverse properties. Key applications include:

Piping: Due to its resistance to moisture and chemicals, polyethylene is used to produce water and gas pipes. These pipes are used in water and gas distribution systems due to their flexibility and high resistance.

Packaging: Polyethylene is used to produce packaging films, plastic bags, and containers for food and non-food products.

Plastic Containers: This polymer is used to produce various plastic containers such as bottles, cans, and boxes.

Agriculture:Polyethylene is used to produce irrigation pipes, greenhouse films, and plant protection products.

Advantages and Disadvantages of Polypropylene vs Polyethylene

Advantages of Polypropylene

High Heat Resistance: Polypropylene can withstand higher temperatures than polyethylene.

High Hardness and Tensile Strength: This polymer has high hardness and tensile strength, making it suitable for mechanical applications.

Lightweight: Polypropylene is one of the lightest plastics, offering advantages in various industries.

Chemical Resistance: Polypropylene is resistant to many chemicals, including acids and bases.

Disadvantages of Polypropylene

Brittleness at Low Temperatures: Polypropylene becomes more brittle at temperatures below zero.

Low UV Resistance: This polymer has low resistance to ultraviolet (UV) rays and may degrade under sunlight.

Advantages of Polyethylene

High FlexibilityPolyethylene has high flexibility, making it suitable for applications requiring bending and shaping.

– **High Impact Resistance:** This polymer has good impact resistance, making it suitable for impact-resistant applications.

– **Moisture Resistance:** Due to its simple structure and high molecular weight, polyethylene has good resistance to moisture, suitable for water-resistant applications.

– **Chemical Resistance:** This polymer, like polypropylene, is resistant to many chemicals.

Disadvantages of Polyethylene

Lower Heat Resistance: Polyethylene has lower heat resistance compared to polypropylene.

Lower Hardness and Tensile Strength: This polymer has lower hardness and tensile strength than polypropylene.

Potential for Creep under Constant Load: Polyethylene may experience creep under constant load, especially at low temperatures.

Production and Manufacturing Processes

Production of Polypropylene

Polypropylene is produced through the polymerization of the monomer propylene. This process can be done in two main ways: gas-phase polymerization and liquid-phase polymerization. In gas-phase polymerization, the propylene monomer is polymerized in the presence of zeolitic catalysts under specific temperature and pressure conditions. In liquid-phase polymerization, the propylene monomer is polymerized in an organic solvent in the presence of a catalyst.

Production of Polyethylene

Polyethylene is produced through the polymerization of the monomer ethylene. This process can be done in three main ways: high-pressure polymerization, low-pressure polymerization, and gas-phase polymerization. In high-pressure polymerization, the ethylene monomer is polymerized under high-pressure and high-temperature conditions. In low-pressure polymerization, the ethylene monomer is polymerized in the presence of zeolitic catalysts under specific temperature and pressure conditions. In gas-phase polymerization, the ethylene monomer is polymerized in the gas phase in the presence of a catalyst.

Recycling of Polypropylene and Polyethylene

Recycling polymers is crucial as it helps conserve natural resources and reduce environmental pollution. Both polypropylene and polyethylene are recyclable, although their recycling processes may differ.

Recycling of Polypropylene

Polypropylene has high recyclability due to its unique physical and chemical properties. The recycling process includes collecting, washing, shredding, and remelting the polymer. Recycled polypropylene can be used to produce new products such as household goods, automotive parts, and packaging materials.

Recycling of Polyethylene

Polyethylene also has good recyclability due to its simple structure and high molecular weight. The recycling process includes collecting, washing, shredding, and remelting the polymer. Recycled polyethylene can be used to produce new products such as pipes, plastic films, and packaging containers.

Main Differences Between Polypropylene vs Polyethylene

The main differences between Polypropylene vs Polyethylene can be examined in several areas:

Differences in Molecular Structure

Polypropylene and polyethylene differ in molecular structure, giving them distinct physical and chemical properties. Polypropylene has a semi-crystalline structure, providing high hardness and tensile strength, while polyethylene has a simple structure and high molecular weight, providing high flexibility and impact resistance.

Differences in Physical and Chemical Properties

Polypropylene has higher heat resistance and hardness compared to polyethylene, while polyethylene has higher flexibility and impact resistance. Both polymers are resistant to chemicals, but polypropylene becomes more brittle at lower temperatures.

Polypropylene vs Polyethylene in Applications

Due to its high heat resistance and hardness, polypropylene is used in packaging, textiles, automotive, and household goods industries. In contrast, due to its flexibility and impact resistance, polyethylene is used in piping, plastic films, containers, and agricultural products.

Differences in Manufacturing Processes

Polypropylene and polyethylene are produced through the polymerization of propylene and ethylene monomers, respectively. However, their polymerization processes may differ. Polypropylene is mainly produced through gas-phase and liquid-phase polymerization, while polyethylene is produced through high-pressure, low-pressure, and gas-phase polymerization.

Conclusion

Polypropylene and polyethylene are two common types of thermoplastics with unique physical and chemical properties, making them widely applicable in various industries. The main differences between Polypropylene vs Polyethylene lie in their molecular structure, physical and chemical properties, applications, and manufacturing processes. Both polymers are recyclable and can help conserve natural resources and reduce environmental pollution. The choice between polypropylene and polyethylene should be made based on the specific needs of each application.