Steel 304 is an alloy that forms the backbone of modern industry, used to produce a wide range of structures and various parts. Essentially, Steel 304 is composed of carbon and iron, but by alloying it with other elements, a vast array of steel types with unique properties can be created. One of these elements is chromium; when added to steel, it creates stainless steel. Chromium significantly increases iron’s resistance to corrosion. Adding other elements can impart additional properties to the alloy; for example, nickel enhances the flexibility of steel. The most commonly used member of the stainless steel family is type 304, which constitutes half of the stainless steel used worldwide. Sometimes, it is still referred to by its old name, 18/8, indicating its composition of 18% chromium and 8% nickel. In this article, we will explore the types, features, and applications of the most famous type of stainless steel, namely grade 304 stainless steel.

Types of Stainless Steel 304

stainless steel 304 is one of the most widely used types of stainless steel. Due to its high resistance to rust and corrosion, it is used in various industries. 304 stainless steel includes several different types, each with specific characteristics and applications.

30 Stainless Steel

Grade stainless steel304 has an austenitic structure, with chromium and nickel being its primary elements. This combination not only provides corrosion resistance but also enhances the formability and weldability of the steel. This type is the most common type of steel used for making sinks and cookware.

Stainless Steel 304L

This type of steel has the lowest carbon content among the stainless steels 304. The lower carbon content reduces carbide precipitation during welding or heating, allowing the alloy to remain welded even in highly corrosive environments. Using 304L steel also reduces the need for post-weld heat treatment (annealing), saving time and energy. In practice, grades 304 and 304L have very little difference, but 304L is better suited for welding thicker parts that require stronger welds. Both types can be used for producing sheets and pipes.

Steel 304H

This type has the highest carbon content, which increases its resistance to high temperatures. When both heat resistance and corrosion resistance are needed, such as in the dairy industry, this steel is the best choice. This steel does not allow bacteria to grow, making it suitable for water treatment as well. Due to its reasonable price, it is also used in architectural applications.

Steel 304 Sheets and Their Appearance

Polished Stainless Steel 304 Sheets

The surface of stainless steel sheets can be polished and finished to make them shiny and bright. This finishing process makes the sheet’s surface bright and free of stains and rust, making it suitable for applications such as interior decorations, kitchen appliances, medical equipment, and more.

Brushed Stainless Steel 304 Sheets

Brushed stainless steel 304 sheets have a textured surface produced by grinding. This textured surface provides aesthetic appeal and anti-slip properties. Its attractive appearance makes this steel popular in interior decoration and design.

Matte Stainless steel 304 Sheets

Matte finish stainless steel304 sheets, with their non-glossy appearance and high resistance to corrosion, have diverse applications in various industries.

Chemical Composition of Stainless steel 304

Grade stainless steel304 mainly consists of iron, which makes up between 66% to 75% of its composition. It also contains between 17.5% to 20% chromium and between 8% to 11% nickel. Additionally, stainless steel304 may include small amounts of other elements such as silicon, sulfur, phosphorus, and manganese.

Chemical Composition of Stainless steel 304 Alloys

| % | 304 | 304L | 304H |

| C | 0.0-0.07 | 0.0-0.03 | 0.04-0.08 |

| Mn | 0.0-2.0 | 0.0-2.00 | 0.0-2.0 |

| Si | 0.0-1.00 | 0.0-1.00 | 0.0-1.0 |

| P | 0.0-0.05 | 0.0-0.05 | 0.0-0.04 |

| S | 0.0-0.03 | 0.0-0.02 | 0.0-0.02 |

| Cr | 17.50-19.50 | 17.50-19.50 | 17.00-19.00 |

| Ni | 8.00-10.50 | 8.00-10.50 | 8.00-11.00 |

| Fe | Balance | Balance | Balance |

| N | 0.0-0.11 | 0.0-0.11 | 0.0-0.10 |

Mechanical Properties of Stainless steel 304

Mechanical Properties for Stainless steel 304 Alloys – Sheet Up to 8 mm Thickness

| Grade | 304 | 304L | 304H |

| (MPa) | 540 – 750 | 520 – 700 | 560 – 800 |

| (MPa) | 230 Min | 220 Min | 240 Min |

| A50 mm | 45 Min % | 45 Min % | – |

Mechanical Properties for Stainless steel 304 Alloys – Sheet 7.5 to 8 mm Thickness

| Grade | 304 | 304L | 304H |

| (MPa) | 520 – 720 | 500 – 700 | – |

| (MPa) | 210 Min | 200 Min | – |

| A5 | 45 Min % | 45 Min % | – |

Mechanical Properties for Stainless steel304 Alloys – Bar Up to 160 mm Diameter

| Grade | 304 | 304L | 304H |

| (MPa) | 500 – 700 | 500 – 700 | 500 – 700 |

| (MPa) | 190 | 175 Min | 185 Min |

| A50 mm | 45 Min % | 45 Min % | 40 Min % |

| Hardness | 215 Max HB | 215 Max HB | – |

Thermal Resistance of Stainless steel 304

304 stainless steel 304 has good oxidation resistance. However, for water corrosion resistance, continuous use at temperatures of 425-860°C is not recommended. In such cases, 304L is recommended due to its resistance to carbide precipitation. For applications requiring high resistance at temperatures above 500°C up to 800°C, grade 304H is more practical.

Calculating the Weight of Stainless Steel

To calculate the weight of stainless steel, you need information about the type and density of the steel, as well as its dimensions including length, width, and thickness. With this information, you can calculate the weight using the following formula:

Weight = length x width x thickness x density

Depending on the units you use (e.g., centimeters and grams), the final weight will typically be in grams or kilograms. For example, suppose you have a steel sheet with dimensions of 100 cm by 50 cm by 2 mm and you are using carbon steel with a density of approximately 7.85 g/cm³. You can calculate the weight as follows:

Weight = 100 cm x 50 cm x 0.2 cm x 7.85 g/cm3

Therefore, the weight of the steel sheet in this example is 785 grams or 0.785 kilograms.

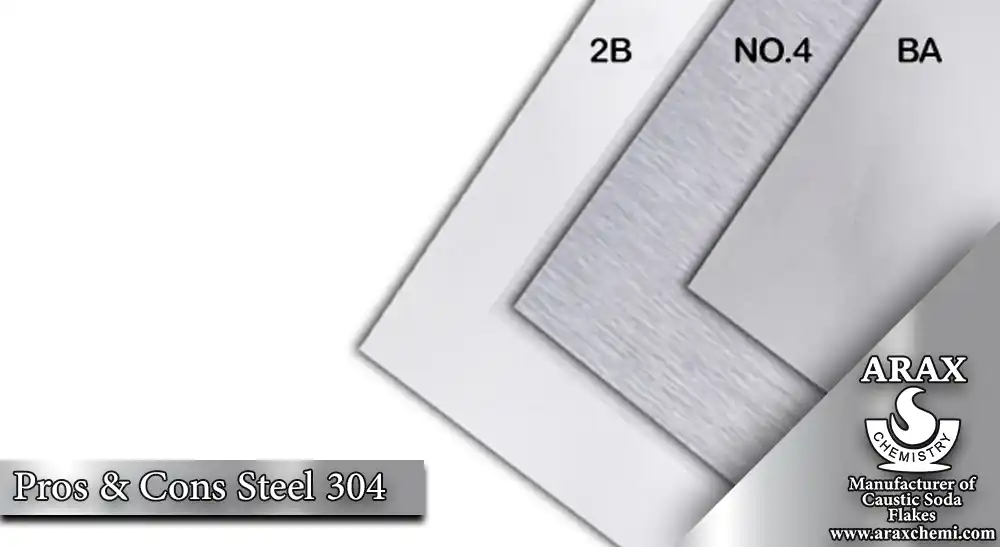

Pros & Cons of Grade Stainless Steel 304

304 stainless steel, despite its many advantages, also has some disadvantages. Knowing these can help you make the best choice to meet your needs.

Advantages

High Resistance: Grade 304 is one of the most resistant stainless steel alloys to corrosion, rust, and oxidation.

Durability: stainless steel 304 can withstand adverse conditions and temperatures.

Cost-effective: steel304 is relatively inexpensive compared to other metals, making it a popular choice for many applications.

Low Maintenance: This steel requires little maintenance, making it ideal for use in situations where frequent maintenance is not feasible.

Disadvantages

Susceptibility to Stress Corrosion Cracking: Grade 304 can experience stress corrosion cracking in some environments, such as high chloride solutions.

Low Tensile Strength: Its tensile strength is relatively low, making it more prone to deformation and cracking compared to other metals.

Sensitivity to High-Temperature Corrosion: It is susceptible to corrosion at high temperatures.

Applications of Stainless steel 304 Sheets

For custom-made parts, stainless steel 304 is the best choice for you. Knowing its other applications can also help you select the most suitable type of steel for your needs.

Food Industry

304 stainless steel 304 is a popular choice for equipment used in the food industry. It is highly resistant to corrosion and easy to clean and

sanitize. Therefore, it is commonly used for:

- Storage tanks

- Mixers

- Bowls

- Counters

- Work surfaces

- Dairy processing plants

- Distillation equipment

Pharmaceutical Equipment

Type 304 is often used for pharmaceutical equipment due to its ease of cleaning and sterilization. This steel is used to produce:

– Tanks

– Pipes

– Valves

– Centrifuges

– Other components used in pharmaceutical processing

Kitchen Equipment

Grade 304 is a popular choice for kitchen appliances due to its high durability and low maintenance requirements. This steel is used for:

– Refrigerator and freezer components

– Dishwashers

– Hoods

– Other appliances

Architectural Applications

Grade 304 is often used for architectural applications due to its attractive finish and strong resistance to rust. This steel is commonly used for:

– Window frames

– Cladding

– Railings

Transportation

For producing parts needed for transportation, stainless steel 304 is a popular choice. This steel is often used to produce:

– Fuel tanks

– Exhaust tanks

– Automobile parts

– Buses

– Trucks

– Other transportation equipment

Conclusion

stainless steel304 is composed of a combination of iron, chromium, and nickel. This alloy has unique properties that make it a top choice for a wide range of applications. One of its key features is its high resistance to corrosion. steel304 performs well against oxidation and the effects of corrosive substances such as acids, alkalis, and salts, making it very suitable for use in environments where it may come into contact with chemicals. Additionally, the high strength and durability of steel 304 make it an ideal choice in many different industries. This alloy can withstand impact, stress, and pressure, preventing fatigue and failure. These characteristics make it a strong and stable structural material that can withstand harsh conditions and environments requiring high strength.