Sodium hydroxide (NaOH) is one of the most widely used and powerful chemicals used in various industries as a strong base and alkali. This chemical compound is able to change the pH of the solution and provide various properties in industrial processes. One of the most important uses of caustic soda is in dyeing industries. The use of caustic soda in dyeing industries can have significant effects on the process and final result of dyeing. In this article, we are going to discuss the uses of caustic soda in dyeing industries, the types of dyeing methods, the difference between traditional and industrial dyeing.

Types of dyeing industries methods

In dyeing, different methods are used to apply color to materials. Below, I briefly mention some types of dyeing industries methods:

- Traditional dyeing: In this method, natural dyes such as plants, insects and minerals are used for dyeing. This method is based on traditional and manual processes such as complete immersion of the product in the dye solution.

- Industrial dyeing: In industrial dyeing, synthetic and chemical dyes are used. This method includes the use of different chemicals such as azo dyes, fluorescent dyes and reactive dyes. Industrial dyeing usually uses more advanced methods such as cotton dyeing, polyester dyeing and nylon dyeing.

- Electronic dyeing: In this method, electrochemical principles are used for dyeing. By using electric current, it transfers the dye solution to the surface of the material. This method is usually used in dyeing metals and different surfaces.

- Dyeing clothes with light: In this method, laser light or fluorescent light is used to dye clothes. By irradiating light to the surface of the fabric, the color dissolved in the garment is absorbed and stabilized.

- Polymer dyeing: In this method, dyes are placed inside the polymer structure as a solution. This method produces clothing and other products whose color is fixed within the structure of the material.

These are just some of the dyeing methods and each of them has its own details and processes.

Materials used for traditional and industrial dyeing

In traditional and industrial dyeing, different materials are used to create color in materials. Below, you can find common ingredients in each of these methods:

Traditional dyeing:

- Plants: for example, leaves and roots of plants such as tea, saffron, lotus, barberry and mango.

- Insects: such as silk worms, red worms and skin worms.

- Minerals: such as iron, zinc, cobalt, copper and red red.

Industrial dyeing:

- Azo dyes: chemicals from the azo family that are used in various colors such as red, yellow, blue and green.

- Fluorescent dyes: Dyes that can produce dazzling and bright colors when exposed to ultraviolet (UV) light.

- Reactive dyes: dyes that easily stick to fibers and cannot be washed. These dyes are usually used to dye clothes.

- Azoelec dyes: dyes in which azo infrareds are used and are fixed on fibers.

It should be noted that these are just a few examples of common materials in traditional and industrial dyeing. Also, in industrial dyeing, dyes and various auxiliary materials are also used so that the colors are better fixed in the fibers and have special characteristics.

Application of caustic soda in dyeing

pH adjustment

Caustic soda is used as a strong base to adjust the pH of dyeing dyeing industries solutions. In dyeing processes, the pH of the solution can have a great effect on the color and final quality of the product. By adjusting the pH to a suitable value using caustic soda, it is possible to create optimal conditions for color fixation in fibers.

Buffering

Sodium hydroxide can also act as a buffer. Buffers are substances that minimize pH changes and maintain pH stability. In dyeing processes, using caustic soda as a buffer can help maintain pH stability of solutions and control pH changes.

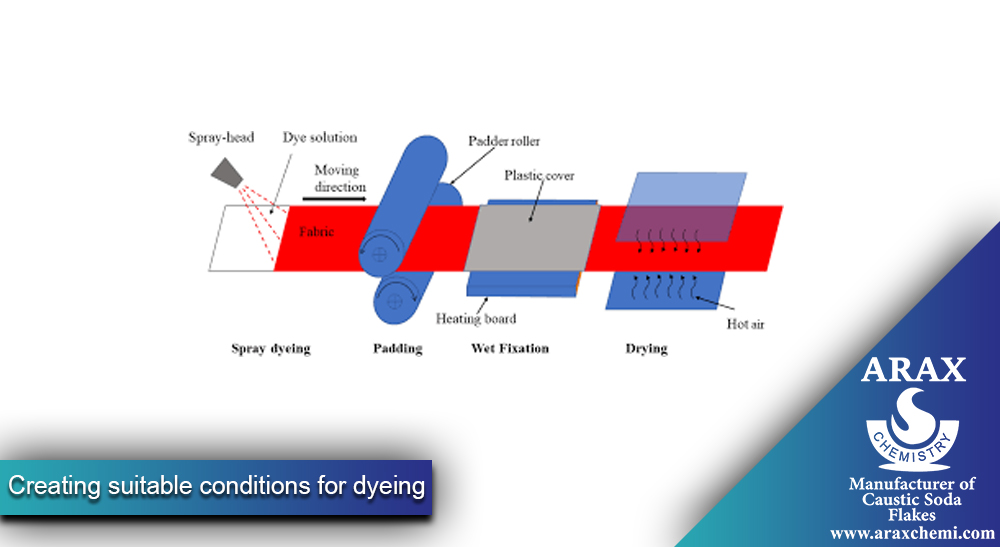

Creating suitable conditions for dyeing

the use of Sodium hydroxide can be effective in improving the quality of dyeing and better stabilization of color in fibers. In dyeing processes, adjusting the pH of the solution to an appropriate amount using caustic soda can improve the quality of dyeing and cause better color stabilization in fibers.

Adjustment of chemical solutions

In general, the use of caustic soda in dyeing industries is to adjust pH, control pH changes, improve dyeing quality and stabilize color in fibers. However, for the correct use of caustic soda in dyeing, it is necessary to follow the instructions and amounts specified by the manufacturer and to observe the necessary care and caution in using this substance.

In general, the use of caustic soda in dyeing is to adjust pH, control pH changes, improve dyeing quality and stabilize color in fibers. However, for the correct use of caustic soda in dyeing, it is necessary to follow the instructions and quantities specified by the manufacturer and to observe the necessary care and caution in using this material.

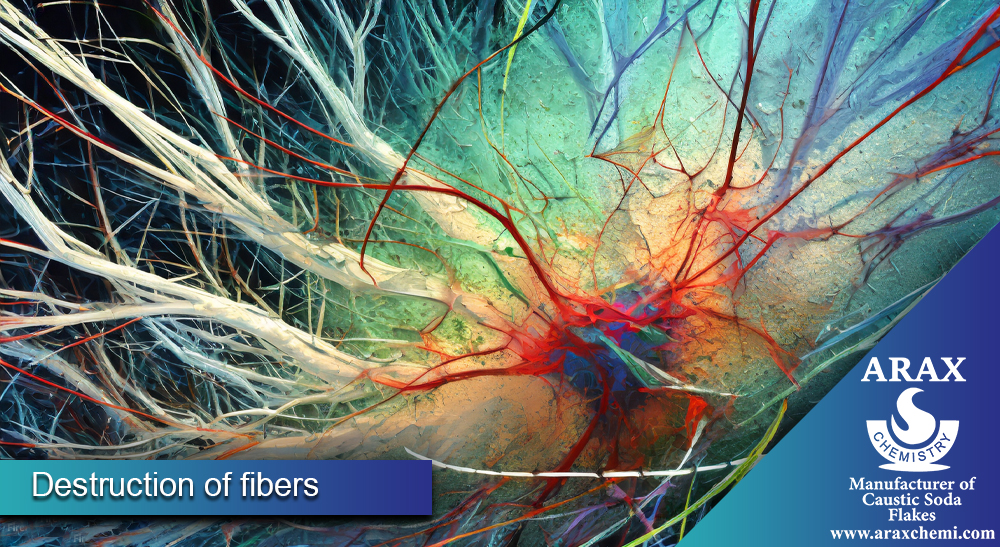

Baking soda along with hydrosulfite is used for dyeing with indigo and some other colors. These chemicals play important roles in the dyeing process. Concentrated alkali solution (37-40% caustic soda) does not show severe destruction on wool in 5 minutes at room temperature. Instead, it separates the wool scales. In the past, this method was commonly used to remove scale in the wool industry.

5% caustic soda solution dissolves wool fibers in maximum 5 minutes at boiling temperature. Because at high temperatures, the pores of the fibers open and dyes easily destroy the fibers. If low temperatures are used, less destruction occurs. After performing any alkaline operation, it is necessary to neutralize using acidic substances. This action is necessary due to the penetration of the remaining alkali into the core of the fibers in a long period of time and the destruction of the wool.

The effect of using caustic soda in dyeing

The use of caustic soda in dyeing industries can have various effects. Below we examine the important effects that are likely to occur with the use of caustic soda in dyeing

pH change

Sodium hydroxide increases the pH of the solution. This change in pH can have a huge impact on dyeing, as the pH of the environment can affect dyes and pigments and change their color.

Solubility

Caustic soda can dissolve some substances in its solution or increase their solubility. This can lead to better and more uniform dyeing on wool or other materials.

Fiber destruction

Using Sodium hydroxide directly on wool fibers may destroy or damage them. Therefore, in order to avoid damage to the fibers, the contact time with Caustic soda should be limited and the necessary care should be observed in the time and temperature of its use.

Effect on color

Caustic soda may affect color and pigments used in dyeing. Some dyes can discolor or degrade under alkaline conditions. Therefore, in choosing colors and pigments to use in the presence of caustic soda, these possible effects should be considered.

Cleaning

Caustic soda may be used to clean and clear woolen pieces before dyeing. This cleaning can remove the pollution, dirt and oils in the fibers and prepare the surface of the wool for dyeing.

Note that the exact effects of caustic soda in dyeing depend on other factors such as temperature, contact time, type of dye and materials used. Also, the experience and expertise of the employer is also influential in creating different results. As a result, to achieve better and desirable results in dyeing, it is recommended to work with the advice and guidance of dyeing experts.

Since working with alkaline chemicals carries many risks, safety in working with these materials is very important.

last word

Caustic soda can have significant effects in dyeing industries. Using it can change the color, destroy the fibers and affect the pigments. To avoid these effects, suitable colors and pigments should be selected and suitable conditions such as temperature and contact time should be observed. Also, caustic soda can be useful in pre-dyeing cleaning and surface preparation of wool. Finally, to achieve better results, it is recommended to consult with experts specializing in this field and thoroughly investigate the effects of caustic soda.