Due to the existence of different types of plastic, the use of caustic soda in plastic recycling is different from the recycling of other materials. Therefore, it is necessary to recycle different types of plastics separately. To put it simply, each type of plastic must be recycled independently from other types. Otherwise, the recycling process will face challenges. Polyethylenes, polypropylenes and polyamides are recycled together. This is because in the recycling process, we crush the plastic material and then melt it and put it back for use. If a mixture of different plastic materials, such as disposable containers, are recycled with different types, it may cause heterogeneity in the composition due to the difference in melting point. this article, we are going to examine the types of plastic materials and the use of caustic soda in plastic recycling.

Analyzing plastic materials in nature takes thousands of years and is extremely difficult. Therefore, finding a solution to recycle these materials is essential. In other words, plastic recycling requires special methods and processes to make these materials reusable in the best possible way and to minimize the environmental impact caused by burying them in nature. In

Plastic

Plastic is a structural material that is used in many products on a daily basis. This material consists of polymers that are produced naturally or from petroleum sources. Polymers are made up of long chains of repeating units known as monomers. Plastics are used in various industries due to their special characteristics, such as lightness, flexibility, resistance to water and chemicals, thermal and electrical insulation, malleability and the ability to produce in different ways. Plastics are used in various industries such as packaging, automotive, electronics, medicine, construction and many others. Also, plastics may be used as fillers in combination with other materials such as metals in industry to add specific properties such as lightness and strength to products.

The advantages of using plastics include lightness and ease of production, flexibility of shaping, resistance to corrosion, thermal and electrical insulation, stability against various environmental conditions, recyclability and reduction of natural resource consumption. However, excessive use of plastics and their lack of proper management can lead to environmental problems such as soil and groundwater pollution. Therefore, the sustainable use and recycling of plastics has been considered to reduce negative environmental impacts.

Recycle sign

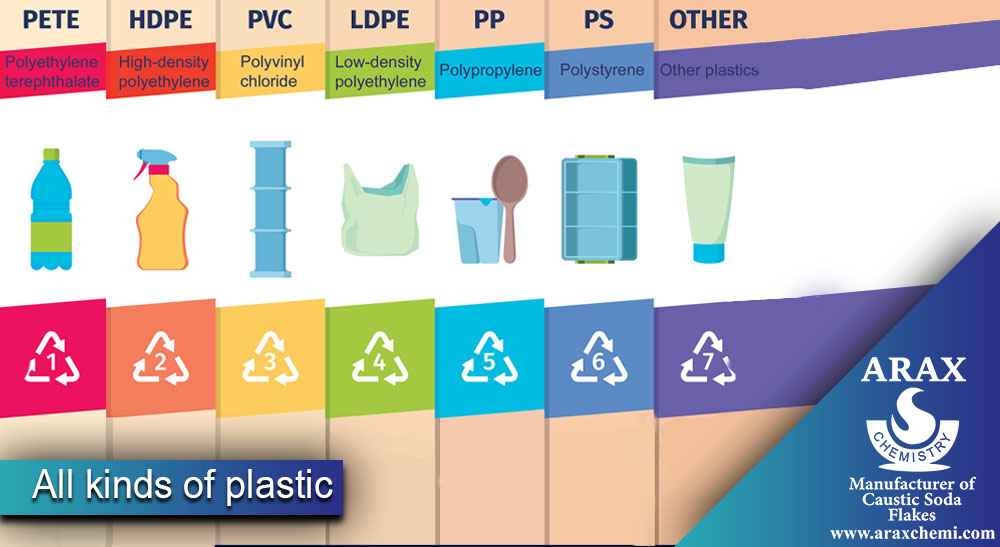

Since 1988, thanks to the creation of the Resin Identification Code, or RIC, it’s been easy to tell what type of plastic many products, packages, and containers are made of. It is the number enclosed in a triangle that appears on many plastic items as a guide to its recyclability, but although the symbol originally consisted of the familiar “recycling symbol” of three arrows arranged in a triangle, all plastics They are not marked like this. Actually Recyclable Recently, it is common to see a solid triangle instead of triangular “recycling” arrows in an attempt to reduce the risk of misinterpretation of non-recyclable plastics. Below are some types of plastic and their characteristics:

All kinds of plastic

Plastic is divided into different types. In the following article, we will explain seven specific RIC codes of plastic types.

-

Polyethylene (Polyethylene – PE)

Two main types: low-density polyethylene (LDPE) and medium-density polyethylene (HDPE).

Applications: shopping bags, milk bottles, pipes, children’s toys.

-

Polypropylene (Polypropylene – PP)

High resistance to heat and chemicals.

Applications: food containers, bags, pipes, household items.

-

PET (Polyethylene Terephthalate – PET)

High transparency and lightness.

Applications: Beverage bottles, synthetic fibers, textile fibers.

-

Polystyrene (Polystyrene – PS)

Light and light.

Applications: cups, disposable containers, thermal insulation.

-

Polyvinyl Chloride (Polyvinyl Chloride – PVC)

Resistant to water and heat.

Applications: pipes, cables, clothing, windows and doors.

-

Acrylic (Polymethyl Methacrylate – PMMA)

High transparency similar to glass.

Applications: showcases, interior and exterior of buildings, home appliances.

-

Polycarbonate (Polycarbonate – PC)

High resistance to breakage.

Applications: bottles, household appliances, electronic appliances.

-

Other: General category for acrylic, nylon and other plastics.

Each type of plastic has its own characteristics and is selected based on the desired type and application. But it should be noted that environmental problems related to plastic waste and their unsustainable use have been taken into consideration and efforts to use recyclable plastics and environmentally friendly solutions are increasing.

Why are some plastics not recycled?

Some types of plastic are not cost-effective or environmentally effective to recycle, and accepting them all indiscriminately can make recycling efforts for other types of plastic more difficult.

For example, plastic film, plastic wrap and thin plastic bags pose a risk of clogging processing machinery if they are collected together with larger, heavier and more rigid recyclable plastics, which is why it is important to place them in plastic recycling bins. Do not post unless you know. are acceptable

The history of using caustic soda in plastic recycling

The use of caustic soda in plastic recycling is an advanced and new technology that has been used in recent decades for the optimal management of waste and reducing the consumption of natural resources, especially in the field of plastic. Below we understand the history of this process better:

1970s

In this period, due to the significant increase in plastic consumption and the increase in the volume of plastic waste, the need for plastic recycling solutions was felt. The recycling process in this era was often done physically.

1980s

With the advancement of technology and better knowledge in the field of chemistry and engineering, the plastic recycling process started to be developed using more advanced technologies such as caustic soda.

1990s

The development of polymer technologies and a better understanding of the different properties of plastics helped to create more sophisticated and accurate recycling methods. caustic soda was considered as one of the recycled materials.

2000s

With the development of new technologies in the field of chemistry, the recycling process using caustic soda was used and was able to play an important role in improving the performance of the plastic recycling process.

At the moment

The use of Caustic soda as a recycled material has been approved by industry and researchers. More advanced technologies and more optimized processes for plastic recycling using caustic soda are being developed and improved.

In general, the history of the use of caustic soda in plastic recycling shows that this technology has changed from a simple process to an advanced and optimal method for managing plastic waste and preserving the environment.

Application of caustic soda in plastic recycling

Caustic soda is one of the chemicals used in the plastic recycling and recycling industry. This chemical compound is alkaline and is used as a strong chemical agent in plastic recycling processes. Plastic recycling is a complex process that is required to separate and recycle usable materials into new plastics. One of the important steps in this process is the separation of different polymers from each other. These materials may be available in different plastic compounds with different physical and chemical properties.

caustic soda is used as an opening agent in the plastic recycling process. By mixing the plastic with caustic soda and applying heat, the bonds between the polymer chains of the plastic are broken. This process is known as hydrolysis and breaks down the plastic into smaller molecules. By applying caustic soda, the polymers are broken down into smaller molecules that can be recycled back into the plastic manufacturing process. These smaller molecules are used as raw materials in the production of new plastics

Using caustic soda in plastic recycling has advantages, including:

- Easier separation and recycling of polymers: Caustic soda breaks down plastic into smaller molecules that are easier to separate from each other. This process increases the efficiency of plastic recycling.

- Reducing the amount of plastic waste: By using caustic soda in the plastic recycling process, the amount of plastic waste is reduced. This means saving natural resources and preserving the environment.

- Higher quality of recycled products: By using caustic soda, the amount of pollution and pollutants in recycled plastic is reduced. This makes the recycled products have higher quality and can be used in different industries.

Also, the use of caustic soda in the plastic recycling process can reduce production costs. Caustic soda is available in the market as an accessible and economical material, and its use in the plastic recycling process can bring economic improvements.

However, in the use of caustic soda in the plastic recycling process, there is a need for proper management and safety of this chemical. This includes the use of safety equipment, precise control of temperature and time, and proper management of waste from the hydrolysis process.

Advantages and disadvantages of using caustic soda in plastic recycling

Advantages

Reducing dependence on natural resources

Using caustic soda in plastic recycling means reducing the need for new raw materials from natural sources. This action helps to preserve natural resources and reduce pressure on the environment.

Recycling of plastic materials

Caustic soda has high recycling potential. These materials can improve the steps of the recycling process and help to reproduce plastic products.

Reducing plastic waste

Using caustic soda helps reduce the amount of plastic waste in landfills and reduces their negative environmental impact.

Energy conservation

The production of caustic soda consumes less energy than the production of new plastic materials. This helps to reduce energy consumption and greenhouse gas emissions.

Recycling of different plastics

As a multi-elastic recycling material, caustic soda can recycle various types of plastics, which increases its wider application.

Disadvantages

Low quality in some cases

In some cases, caustic soda may have a lower quality than the original plastic material. This issue may affect the production of some products.

Need for purification and polishing process

After recycling, caustic soda requires purification and polishing processes to solve problems related to pollution and various particles. This step may take time and increase the cost of recycling.

Limitations on applications

Some specialist applications require special characteristics and higher quality of plastic materials, which in some cases Caustic Soda cannot respond to them.

Recycling costs

The costs associated with the recycling process, including separation and treatment, may offset some of the energy benefits derived from recycling.

Dependence on the recycling market

The market value for caustic soda and recycled products may vary, and this dependence may affect the economics of recycling programs.

Conclusion

The use of caustic soda in plastic recycling is an example of technological advancement in plastic waste management. This method reduces the consumption of natural resources, reduces the amount of waste and creates high quality plastic products. It emphasizes the positive effect of this technology in waste management, local economy and environmental protection. Increasing public awareness also emphasizes the importance of this strategy for the society.